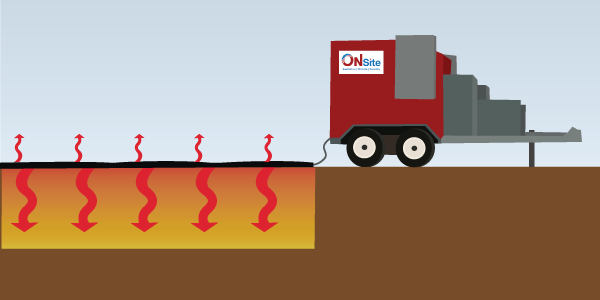

Construction work in the winter months can be tricky, but that doesn’t mean that the work can stop. If you are pouring concrete on the ground, on an elevated surface, or in wall enclosures, hydronic heat could be the fastest way to ensure evenly cured concrete. Using hydronic heating or ground thaw equipment can speed up your curing process and creating uniformly cured concrete cheaply and quickly.

Hydronic systems transfer heat by circulating a glycol / water solution in a closed system of pipes or hoses. These systems transfer heat more efficiently than forced air systems without the negative effects of exhaust gases and drying of the concrete from air movement. The specific heat of water / glycol solutions is more than six times greater than air. As a result, hydronic heaters can deliver very large quantities of heat at low temperature differentials of 5º C or less between the heat transfer hose and the concrete.

Laying concrete in colder temperatures can mean slow curing times and could cause uneven curing which could be hazardous. The chart below highlights the curing times, as well as the long-term strength of the concrete at different air temperatures.

As you can see, the colder the outside temperature it is, the longer it takes the concrete to reach its final set temperature and long-term strength. By heating the concrete, you can speed curing times and allow your job to move along more quickly.

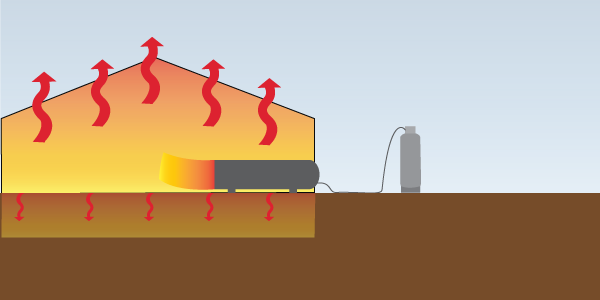

Curing Using Traditional Enclosure Heating Method

Traditional methods of curing concrete in the winter including building enclosures and heating the enclosure with standard heating such as direct fired heat. There are several downsides to using this method of heater such as:

- The time it takes to build the enclosure and set up the heating units. These poly enclosed structures have to be designed and built around the area of the concrete, which wastes precious time and money for your winter project.

- Uneven curing, curling and chalking of the finished concrete.

- Noxious fumes and open flame hazards. Direct fired heaters are safe, but you will have to keep ventilation in mind and find safe places to set the heaters to avoid fire hazards.

- Larger fuel bills because of escaped and un-used heat energy. Since the heat isn’t direct straight into the ground, a lot of the heat escapes before it can be utilized.

Curing Using Traditional Enclosure Heating Method

Traditional methods of curing concrete in the winter including building enclosures and heating the enclosure with standard heating such as direct fired heat. There are several downsides to using this method of heater such as:

- No enclosure to build with an easy setup. You lay out the tubes across the surface that you want to heat and lay insulated blankets over top to save time and money

- Uniform curing since the heat is dispersed across the surface instead of simply heating the air.

- No open flame or noxious fumes. The hydronic heating system is enclosed inside of the trailer and sits outside so no fumes can gather.

- Easy temperature control result in lower fuel costs. All hydronic heating systems come with a thermostat so you can set the temperature and let it do its job.

In a future blog post, we will go over the types of hydronic heater placement you can use on your job site, and how to accomplish optimal heating.

On Site Companies provides hydronic ground heating rentals in our St. Paul / Minneapolis, Rochester and Mankato MN, St. Louis MO and Omaha NE.